Cryogenic Container

Cryogenic liquid containers (called liquid cylinders) are double-walled vacuum vessels designed for reliable and economical transportation and storage of cryogenic gases at temperatures that typically drop below -130degF (9oC).

Feature

A liquid container offers two main advantages over compressed gas cylinders:

1) it stores large volumes at relatively lower pressure and

2) it provides access to cryogenic liquids that are easily manageable compared to compressed cylinders. Cryogenic containers may sometimes be incorrectly called “dewars,” although dewars are open nonpressurized vessels meant solely for holding cryogenic liquids.

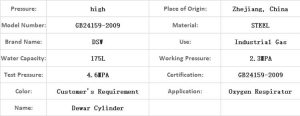

Dewar container Sizes Chart

Specification of Cryogenic Liquid Container

| Model | DSW450-175-1.37 | DSW450-175-2.3 | DSW450-195-1.37 | DSW450-195-2.3 | DSW450-210-1.37 | DSW450-210-2.3 | DSW450-210-3.0 | |

| Nominal volume(L) |

175 |

175 |

195 |

195 |

210 |

210 |

210 |

|

| Effective capacity(L) |

160 |

160 |

177 |

177 |

191 |

191 |

191 |

|

| Dimension(diameter*height) |

Φ510*1557 |

Φ510*1557 |

Φ510*1673 |

Φ510*1673 |

Φ510*1767 |

Φ510*1673 |

Φ510*1673 |

|

| Working pressure (Mpa) |

1.37 |

2.3 |

1.37 |

2.3 |

1.37 |

2.3 |

3.0 |

|

| Safety valve open pressure(Mpa) |

1.59 |

2.41 |

1.59 |

2.41 |

1.59 |

2.41 |

3.45 |

|

| Bursting disk open pressure(Mpa) |

2.41 |

3.6 |

2.41 |

3.6 |

2.41 |

3.6 |

5.17 |

|

| Evaporation rate(Lin)(%/d) |

<2.1 |

<2.1 |

<2.0 |

<2.0 |

<2.0 |

<2.0 |

<2.0 |

|

| Empty weight(kg) |

≈130 |

≈142 |

≈133 |

≈152 |

≈131 |

≈165 |

≈165 |

|

|

Max filling weight (kg) |

LO2 |

≈182 |

≈182 |

≈202 |

≈202 |

≈218 |

≈218 |

≈218 |

| LN2 |

≈129 |

≈129 |

≈142 |

≈142 |

≈154 |

≈154 |

≈154 |

|

| LAr |

≈224 |

≈224 |

≈248 |

≈248 |

≈268 |

≈268 |

≈268 |

|

| LNG |

≈68 |

≈68 |

≈75 |

≈75 |

≈75 |

≈75 |

≈75 |

|

| LCO2 |

— |

≈188 |

— |

≈209 |

— |

≈225 |

≈225 |

|

| Level gauge |

Floating level |

Floating level |

Floating level |

Floating level |

Floating level |

Floating level |

Floating level |

|

| Surface treatment |

Polish |

Polish |

Polish |

Polish |

Polish |

Polish |

Polish |

|

| Base type |

Rubber base |

Rubber base |

Rubber base |

Rubber base |

Rubber base |

Rubber base |

Rubber base |

|

APPLICATION OF Cryogenic Liquid Container

Cryogenic products commonly available in cryo canisters include liquid nitrogen (LIN), liquid argon (LAR), liquid oxygen (LOX), and liquid helium (LHE).

Carbon dioxide and nitrous oxide can also be found as refrigerated liquids in similar containers.

While these containers may appear well insulated, heat can still infiltrate their products due to an enormous temperature gap between cryogenic liquid and ambient conditions.

This heat leak causes some vaporization, which, if left unused, will collect in a space above the liquid and create a pressure buildup.

Head pressure refers to the buildup of air in a container that builds gradually over time and vents periodically through its pressure relief valve, usually venting out via vaporization rates between 0.4% and 3% of its volume per day vaporized through vaporization rates that vary widely within any given day.

It’s normal and safe, making up part of its function.